Main ingredients

Special polymer compounds.

Technical indicators

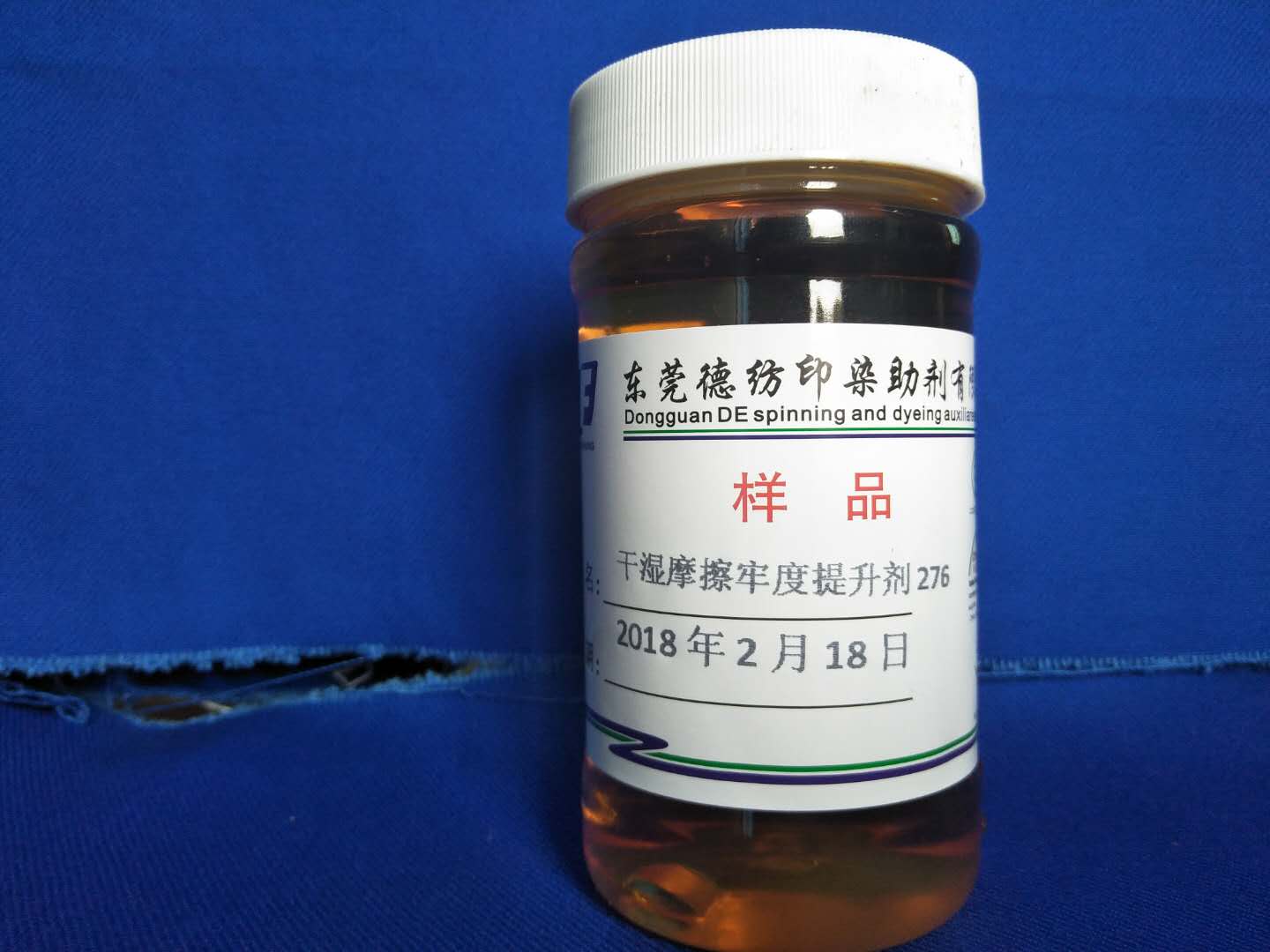

Yellow viscous liquid.

PH (1% aqueous solution)3.0-4.5.

Ionic: cationic/non-ionic.

Solubility: soluble in water.

Performance and characteristics

1. It is used to improve the dry and wet rubbing fastness of various fabrics, such as cellulose fiber (cotton, artificial cotton, modal, viscose fiber)

Polyester, nylon and blended fabric.

2. The dry and wet rubbing fastness of the dark fabrics can be increased significantly, which can be improved by 1-2; Small impact on fabric feel.

Scope of application

Applicable to the dry and wet rubbing fastness of all kinds of fabrics,

Method of use

1. The immersion method

2-4% (O.W.F)

The process at room temperature for 15 to 20 min, drying (120-17 o ℃)

2. The method of pad

(recommended method) dosage: 10-40g /L;

Drying process pad wet rubbing fastness to improve agent (130-170 ℃)

The specific process requests the user to adjust according to the sample.

Matters needing attention

1. Direct cold water is used when the working fluid is less than 35 when used, and the stability is better.

2. Clean the cloth before use; The presence of alkali and electrolyte can lead to a decrease in product stability (with white viscous precipitates)

It is recommended that under acidic conditions, the pH value is 4 0-4,5, with better effect and stability,

3. Avoid using water with more impurities (such as well water, river water), and it is recommended to use tap water with water quality below 3o0ppm or soft 7.

The material.

4. In case of the need to be used with the post-finishing auxiliaries, the stability test should be done in advance; Or after finishing, solid color step.

5, when used for polyester fabric, suggest to finalize the design temperature does not exceed 170 ℃, in order to avoid the heat of disperse dye sublimation.

Packaging and storage

125KG plastic bucket, sealed in the shade and cool place, under normal temperature for 12 months.